Why Epoxy is the Best for Garage Floors

Of any floor in your home, garage floors need to be the toughest and that's why we recommend garage floor epoxy. Think of what an average day looks like in your home. The garage floor withstands the weight of heavy vehicles driving in and out of it and bulky tool chests filled with tools. Children ride bicycles around. Homeowners store motorcycles, boats, and lawn equipment. Teenagers throw sporting goods around. Your concrete flooring needs protection, which is why we highly suggest epoxy for garage floors.

In addition to the normal wear and tear of daily living, we expose our garage floors to elements that we keep away from the rest of our flooring. Harsh chemicals, like cleaning supplies, automobile fluids, debris from tires, and dust blown in, all contribute to the deterioration of concrete garage floors. Extreme heat and cold plague a garage, water rushes in, floors are pressure washed, and left dirty. A painted garage floor looks similar to epoxy; however, it does not offer the protection of an epoxy coating.

What is Garage Floor Epoxy?

A thermosetting resin, epoxy coats existing floors, creating a protective barrier. When a hardener mixes with epoxide resin, the hardener acts as a catalyst. The resulting chemical reaction produces cross-linked polymers, giving the epoxy its strength and durability. Epoxy bonds with the prepared surface, leaving a thick coating. Epoxy floor coatings come in a wide variety of textures, colors, and thickness, depending on the use of your garage.

Benefits of Epoxy for Garage Floors

Long-lasting Durability: Epoxy extends the lifetime of your garage floor, outlasting most flooring materials on the market. Professionally installed epoxy floor systems, when properly maintained, lasts for years. Epoxy floor coatings prevent peeling and cracking from normal wear and tear.

Moisture Protection: We’ve all walked into a garage at some point and smelled mold and mildew. This common problem happens when excess moisture seeps in. Epoxy floors protect against moisture seepage from heat, condensation, leaks, and weather. Not only do mold and mildew exude an unpleasant odor at times, but they also wreak havoc on the stability of your floors and walls. The health problems caused by breathing in toxic mold spores are easily preventable.

Slip-Resistant: Like any floor, epoxy becomes more slippery when the surface is wet. Slip-resistant textures added to epoxy resin protect against slips and falls. This texture adds a layer of skid-protection as well. The anti-slip materials not only make your floor safer, but the variety of textures from light to coarse, offer a unique aesthetic.

Chemical Resistance: Epoxy coatings resist both chemicals and stains. Whether you spill oil or gasoline or leak brake fluid or antifreeze, your epoxy coated garage floor will be safe. Even if the chemical sits for an extended period before you wipe it up, it will not stain. It also resists grease from rolling toolboxes and mechanics equipment like jacks and jack stands. Additionally, epoxy flooring differs from other types of flooring in that it does not emit harmful chemicals or gases.

Easy Maintenance: The seamless surface of epoxy floors makes it easy to run a broom or mop over. Dirt and debris don’t have crevices to hide in, allowing for minimal use of harsh chemicals. A typical maintenance schedule involves running a soft dust mop over the floor weekly to remove debris and prevent scratches. Vacuum visible saw cuts or intentional construction joints monthly. Immediately clean spills with a soft cloth. If a film or grit remains, use a light cleaner.

Aesthetic: Epoxy comes in a variety of colors and textures, patterns, and designs. Decorative quartz, vinyl flake, self-leveling epoxy, and epoxy mortar flooring, each visually unique, all create an exceptionally appealing floor. Decorative quartz epoxy flooring provides ornamental, sanitary, slip-resistant, and exceptionally durable concrete floor coverings. This high-performance epoxy polymer resin combines with color quartz, resulting in a stylish, colorful floor. When adding vinyl flake to epoxy, the unique pattern created provides a look reminiscent of granite. The one-color epoxy coating system of self-leveling epoxy preserves bare concrete without too much flare. Epoxy Mortar Flooring is a 100% solids epoxy combined with graded sand or quartz sand and troweled into place.

Affordable: The cost of epoxy flooring is lower per square foot than most comparable flooring materials. One of the reasons for this is that epoxy is often applied to an already existing concrete floor. The fast installation time and minimal upkeep also keep costs down. The added value provided by a professional epoxy floor installation company includes moisture testing before installation, surface preparation, and the addition of decorative compounds like quartz or vinyl flake. Keep in mind that epoxy flooring systems require anywhere from one to seven coats based on the type of epoxy you choose and the thickness required. Factoring all this in, along with the long lifespan of epoxy flooring, the expense is minimal in comparison to other types of flooring.

Note: (See our Video Below)

Extra Layers of Safety: There are numerous layers of safety offered by epoxy floor coatings. Its reflective quality adds light to the room, providing more visibility. Depending on the type and color used, epoxy can add up to 200% more brightness. Epoxy floors resist extreme heat and even fire. Epoxy resists germs and bacteria. Easily sanitized, epoxy keeps your family healthy.

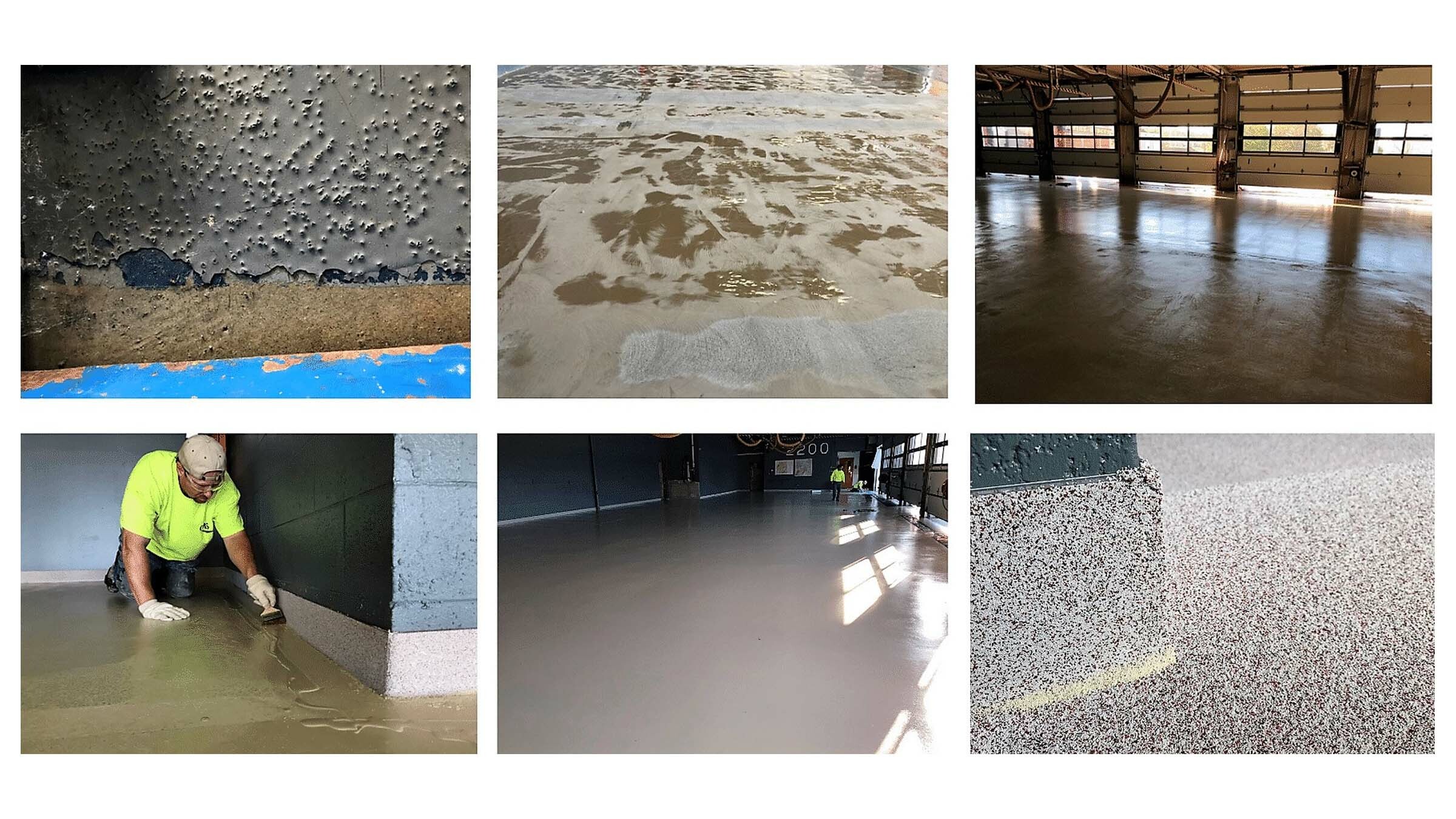

Resurfacing: Uncoated and painted garage floors peel, pit, crack, and chip. Also, age, abuse, and natural wear contribute to the deterioration of an untreated concrete floor. Applying an epoxy floor coating over a damaged existing, concrete floor will turn it into a smooth, attractive, high-performance surface. Replacing an entire concrete floor is expensive and intrusive to your day to day activities. Resurfacing costs significantly less and gives you a functional floor with an original appearance.

The Installation Process

The three most important aspects of installing epoxy floor coatings are safety, preparation, and knowledge. In addition to the installation of your epoxy coating, professional contractors must consider these on every job site to ensure an alluring transformation.

A professional epoxy flooring installer, like Creative Maintenance Solutions, always puts safety first. Before performing any work, the team consults the client and determines their needs. They inspect the concrete for pre-existing coatings and determine the condition of the substrate. Concrete must be structurally sound to continue with an epoxy coating. Installers then implement a plan that includes safety protocols for homeowners and installation technicians.

Upon inspecting your garage floor, your flooring company must perform a humidity, or RH, test. It’s imperative to know the actual moisture content of the concrete substrate. Because the surface does not adequately reflect the condition of the entire slab, installers conduct a relative humidity test. This scientifically-proven method enables flooring professionals to determine the precise time to apply the epoxy floor coating. Skipping this step leads to broken bonds, blistering, and peeling.

Next, your epoxy flooring technician explains the surface preparation process. This includes safely eliminating imperfections from the existing concrete. Dirt, debris, and stains must be removed. Keeping safety in mind, contractors should be wearing protective equipment and using environmentally friendly products. At Creative Maintenance Solutions, we use the most effective surface preparation methods including:

Shot blasting is the process of blasting an existing concrete surface with steel shot (small steel balls) at a high velocity. This removes contamination and laitance, or soft concrete, to reveal a mechanical profile for improved bonding. A powerful dust collection system then removes the concrete dust.

Diamond grinding surface preparation is a form of concrete grinding that cleans, abrades, and leaves the substrate surface smooth. This approach is ideal for preparing the concrete surface for thin applications and sealers, such as waterborne epoxy. It clears away thin coatings and mastics and levels out surfaces on concrete, priming the top for the next coating.

Knowledgeable, professional epoxy coating installers recognize the intricate installation process. Manipulating chemicals, resins, and hardeners is a truly scientific process. Professional installers know how to properly mix ratios to create a solid bond and secure surface. They understand the importance of surface compatibility and the role temperature and humidity play in the curing process. The age, composition, temperature, and condition of existing concrete substrates affect its reaction to an epoxy floor coating. We always recommend hiring an experienced flooring contractor.

Types of Epoxy for Garage Floors

Understanding the different types of epoxy for garage floors makes the selection process easier. While there are hundreds of brands and styles of epoxy, there are three prime categories: 100% solid epoxy, waterborne epoxy, and solvent-based epoxy. The compound makeup of the epoxy determines its category.

At Creative Maintenance Solutions, we recommend 100% solid epoxy. This pure epoxy maintains its’ thickness from application until completely dried. However, this thickness also makes it the most difficult to apply. Because there is no dilution by any water or solvent, 100% solid epoxy is exceptionally strong. It resists stains, chemicals, and abrasions that other epoxies accept. The drying process contributes to the difference in strength between types of epoxies. Solvent and water-based mixtures evaporate, but 100% epoxy cures. Once this occurs, it can never be uncured. The application process for 100% pure epoxy is complex and should be done by a professional concrete technician.

Adding a solvent to pure epoxy gives you a solvent-based epoxy. Solvent-based epoxy produces a glossier surface than other epoxies and can be used in chilly temperatures and high humidity. While not as strong as 100% solid epoxy, solvent-based epoxy is stronger than waterborne epoxy. The solvent slightly reduces its’ strength but is more resistant to petroleum contamination. For this reason, solvent-based epoxy used to be the most common epoxy coating for machine shops and mechanics garages. No longer true because of the high VOC content, experts suggest more environmentally-friendly epoxies. The harmful fumes during installation led to strict regulations that limit, and prevent, the use of solvent-based epoxy.

The main ingredient found in waterborne epoxy is water. This combination is safer than solvent-based epoxies because it is water-soluble. Waterborne epoxy has a faster and easier application process. Errors during the application process are easy to clean up. It has some self-leveling properties, making re-coats straightforward. Referred to as a waterproofing epoxy, waterborne epoxy is significantly less chemically resistant than either solvent-borne or 100% solid epoxy. Applied in thick or thin coats, waterborne epoxy lacks the durability of other epoxy solutions. However, water-based epoxies penetrate porous concrete substrates, making the bond stronger. These epoxy coatings create the same glossy surface and colorful aesthetics. They are environmentally friendly. And, they emit no harmful fumes or bad smells.

Creative Maintenance Solutions Services

Garage floor epoxy coatings continue to be favored for garage floors, basement floors, and all other residential concrete spaces. Concrete floor covering solutions are not just for commercial and industrial environments. Many residential spaces require epoxy floor coatings and innovative solutions to create a unique appearance and promote safety.

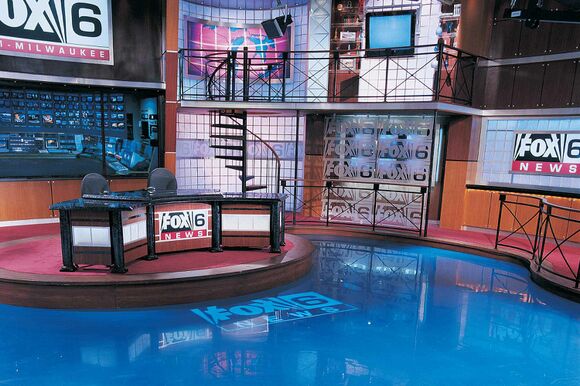

An updated and sound floor turns an ordinary floor in your house into a favorite part of your home. The leader in concrete flooring solutions throughout Milwaukee, Creative Maintenance Solutions, offers epoxy flooring, polished concrete, and surface preparation. With a nationwide reputation as a top-quality concrete coating service provider, Creative Maintenance Solutions provides unparalleled quality and product guarantees. For 30 years, Creative Maintenance Solutions has been committed to providing the most advanced floor covering systems to businesses and residences throughout the United States.

We believe in continually educating ourselves to provide innovative epoxy flooring solutions to homeowners and Fortune 500 companies alike. In our three decades of service, our skilled staff has provided real solutions, top-notch floor coverings, and expert installations. We meet the needs, standards, budgets, and deadlines of all of our clients.

Request an assessment for your concrete flooring project or contact us today to learn more. We know from years of experience at Creative Maintenance Solutions that a beautiful floor finish helps set your space apart from the rest.

Follow along as Creative Maintenance Solutions specialists create distinctive epoxy-finished floors, repair and resurface existing ones, and show you the tips and tricks of creating an amazing floor covering!

GARAGE FLOOR EPOXY

Contact Creative Maintenance Solutions to start your project today!