Finding the Best Epoxy Flooring Contractor

Our Epoxy Flooring Contractor Guide is essential when you're looking to hire the best contractor for your epoxy floor coating project. An important investment as such requires up-front research. The growing trend of decorative floor coatings has given rise to the number of flooring contractors that perform this intricate service. However, many new companies do not have the education and experience that comes from longevity in the business. After 30 years in the concrete flooring industry, Creative Maintenance Solutions has a consistent, proven record of success. We want to pass our knowledge on to you to help you make an informed selection. Let us walk you through our "How to Choose Right Epoxy Flooring Contractor Guide."

What Makes a Reputable Contractor?

Before we delve into our checklist, we want you to understand the characteristics of a reputable epoxy flooring contractor. Trustworthy concrete flooring professionals walk you through the entire process. They explain the difference in materials, including the chemical makeup and reaction, quality, and cost of each option. They describe the detailed application process from surface preparation to curing time. Efficient epoxy experts educate you about after-care and long-term concrete flooring maintenance.

What questions should I ask?

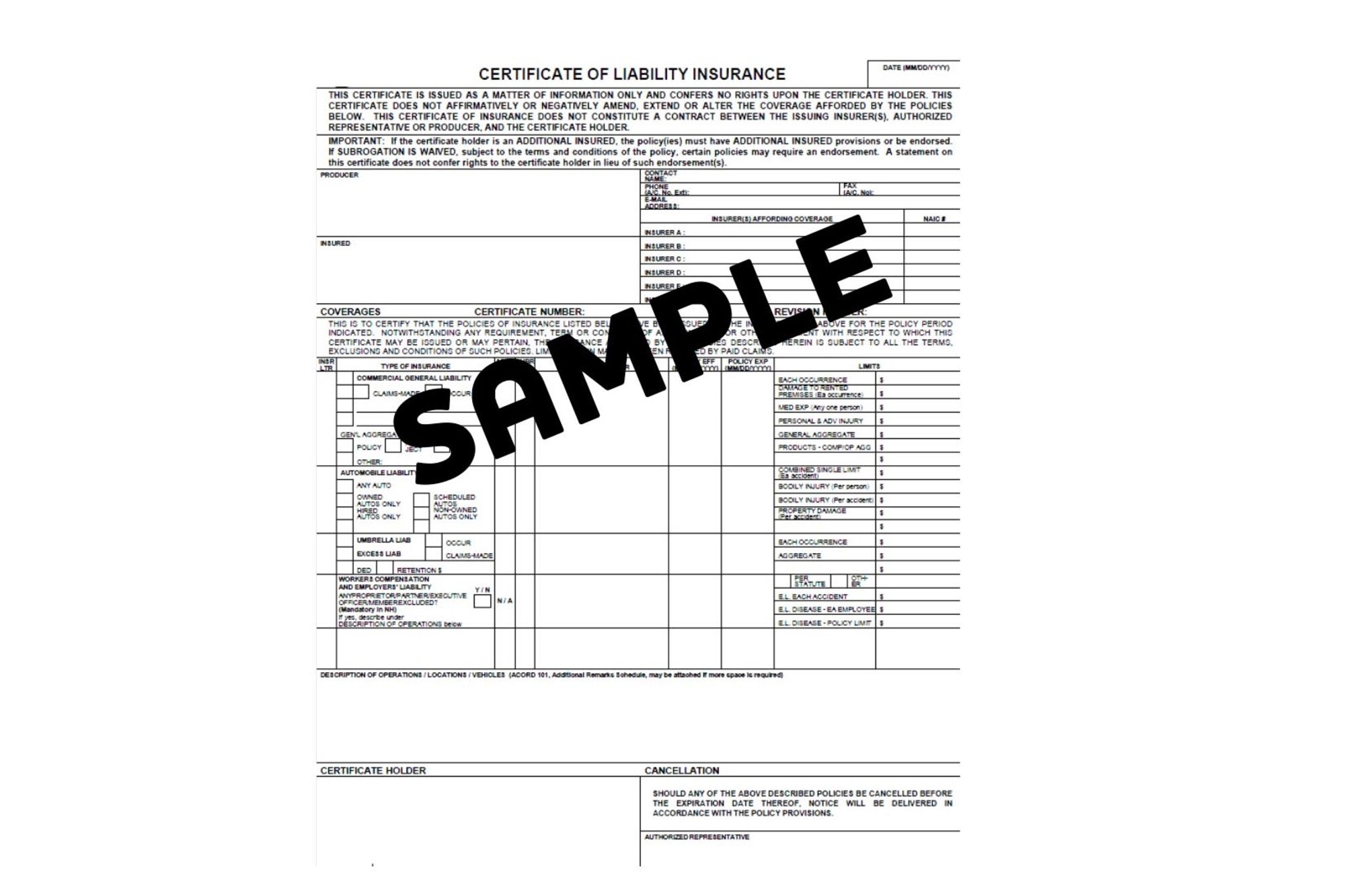

Are you licensed and insured?

Whether you are considering a sole-proprietor or an entire firm, your contractor must have insurance. A general liability policy protects you and them, covering property damage, accidents, disasters, and bodily injury. Inquire about additional coverage such as installation and equipment policies. Request proof of insurance. Once you have this, if you still have questions or concerns, reach out to the insurance company or agent. Solicit information regarding claim limits, policy expiration, and how to file a claim.

A thermosetting resin, epoxy coats existing floors, creating a protective barrier. When a hardener mixes with epoxide resin, the hardener acts as a catalyst. The resulting chemical reaction produces cross-linked polymers, giving the epoxy its strength and durability. Epoxy bonds with the prepared surface, leaving a thick coating. Epoxy floor coatings come in a wide variety of textures, colors, and thickness, depending on the use of your garage.

To confirm licensing, ask the prospective contractor for their license number. Visit your states' Department of Safety and Professional Services website or contact them by phone to verify the licensure. You can also contact your local consumer protection agency for confirmation. Please do not assume that because a number is provided to you, it is current or valid. While a license may have been issued in the past, they are not always renewed and expire. Be sure to confirm the license is a contractor's license. You do not want to find out after an issue that the license is for another trade, like plumbing or electrical.

How much professional experience do you have?

The internet and reality do-it-yourself shows make flooring projects look less complicated than they are. When you're investing in new flooring, it is best to hire a qualified professional. Epoxy floor coatings involve a complex combination of chemicals, environmental factors, and problems that occur. It is an exact science. The more knowledge acquired by flooring installers, the smoother your project will go. Time spent on a project, troubleshooting, and quality of service by a competent contractor surpasses that of inexperienced workers.

The right epoxy flooring contractor details their timeline. They provide information about their current workload and how it affects your project and explain potential issues that may delay completion. Adequately preparing for your flooring project minimizes its' interference in your workflow or home life. Choose a contractor that understands the nuances involved in putting forth a satisfactory epoxy flooring system.

Don't hesitate to request personal references. A short phone conversation with previous clients opens the door to realistic expectations. They offer honest details about the fine points of the company's service, materials, and performance. Ask for before and after photos. They are a fantastic resource when investigating the performance of a flooring contractor. If a company refuses to provide references, it is a sign that you should not hire them.

Excellent Questions to Ask the Concrete Flooring Specialist

How do you prepare a surface?

Preparing your surface is the most critical part of the epoxy floor coating installation. This multi-step process, when done correctly, ensures a long-lasting, beautiful floor coating. Experienced epoxy floor technicians know this is not a task to overlook. While time-consuming, concrete surface preparation prevents costly flooring failures down the road. Conscientious flooring installers take the time to make existing floors look like plain concrete again. This 95% dust-free process increases the bond strength of the new floor, removes floor contaminants, eliminates the use of harsh chemicals, and removes existing coatings or adhesives.

The answer you want to get from a prospective contractor sounds similar to this. By using the latest diamond-grinding and shot-blasting equipment, concrete surfaces are cleaned and prepped. Tiny grooves intentionally left behind create the perfect texture for epoxy to bond with. Using the diamond-grinding or shot-blasting equipment, produces an enhanced bond strength and smooth, seamless surface, regardless of the type of system used. Textured surfaces give the installation crew more control while applying the coating.

Do you have a company website?

While not the only thing to consider, professional websites show contractor credibility. Companies that perform large-scale epoxy jobs regularly showcase their projects on a hosted web site. Photos of previous work let you see the style and quality the company provides.

Professional websites tell you about the kind of business you're hiring. It gives you a look into their staff, their history, association affiliations, and what type of community involvement they have. They are a great tool to help you decide which company will meet your needs. Savvy epoxy flooring companies understand the importance of staying competitive in the market and proudly display their accomplishments.

What kind of warranty do you offer?

Good contractors guarantee their work. They strive to give 100% customer satisfaction. They return to fix any errors or mishaps that occurred during installation. They have experience with a plethora of products and likely have a relationship with the manufacturer.

Creative Maintenance Solutions offers a warranty that is unmatched in the industry! This guarantee includes up to a five-year limited warranty on ⅛" thick floor systems, up to three years on Single Broadcast Flooring Systems, and up to one year on Thin Mil Coating Systems. The warranty covers the craftsmanship, performance, and material.

Do you have employees or do you use subcontractors?

It's imperative that you ask the company if they use employees or subcontractors. You want to know who is responsible for the work being done. Hiring a subcontractor is a common occurrence in any trade. However, you need to decide if you're comfortable with the work structure. While some customers don't mind if a company uses subcontractors, others prefer companies with their crew on staff.

If a company does use subcontractors, it isn't necessary to rule them out. Confirm the experience level of your installers. Find out who is responsible for errors. Is it the company you hired or the subcontractor. Is the subcontractor licensed and insured? Are you paying more money because of contractor markups? A subcontractor should willingly answer all of the same questions you ask the original company.

How much and what type of equipment do you own?

The answer to these questions gives consumers considerable insight into a prospective epoxy flooring contractor. Companies that have been around for an extended period, and plan to stay in business, make investments in themselves. By purchasing their equipment, a contractor shows you they are serious about what they do. Newer companies frequently rent the majority of their equipment, and rentals often mean a company has a large debt.

Sizable commercial and industrial projects require the use of high-end equipment. The more jobs they have, the more equipment they need. Lack of owned equipment can be a red flag for possible delays and quality of their work.

What questions do you have for me?

Trustworthy, epoxy floor system contractors begin the assessment process by asking you relevant questions. To make sure they are giving you the solution you need, be prepared to answer questions like:

- What is the floor used for? A residential garage floor does not have the same requirements as an industrial warehouse or manufacturing plant. Curtailing the primary function of your floor helps the contractor recommend appropriate products and applications.

- What does your floor need to tolerate? The purpose of epoxy floor coatings is to extend the life of your floor substrate. Tell the contractor every type of hazard your floor needs to stand up to - heavy machine traffic, chemical spills, extreme heat or cold, etc. Creating a list in anticipation of this question helps ensure you've covered everything.

- What does your floor need to resist? This answer is going to be similar to the previous one, but mean different things to epoxy experts. For extra protection, additives are applied before, during, or after application of the epoxy coating. These combinations create impact resistance, slip resistance, stain resistance, thermal resistance, and anti-microbial properties - depending on your requirements.

- What do you want your floor to look like? Epoxy floor coatings generate a beautiful aesthetic. Design options include complete customization. Company logos, brand colors, in-laid graphics, and color options increase the professional appearance of your floor. Strategic patterns and designs identify safety and high-traffic areas, making your space safer and more productive. Contractors need to prepare a plan for your specifications.

- Do you have time constraints or project deadlines? Good flooring contractors know how long each step in the epoxy process takes. However, every situation is unique, and every building presents its challenges. Does your business need to remain open during installation? How long can you shut down? Do areas have heavy equipment? How quickly do you need the project completed? These are all things a contractor has to know to schedule accordingly.

Prepare to Explain Why Choose Epoxy Floor Coatings?

Professionally installed and correctly maintained epoxy floor coatings offer many advantages over alternative flooring options. Epoxy floor coatings are a long-lasting, durable flooring solution for residential, commercial, industrial, and institutional floors. Concrete Maintenance Solutions provides the perfect flooring solution for your unique environment - from light to medium to heavy-duty. Epoxy offers a high-performance surface on newly poured concrete floors, as well as existing, damaged floors.

Epoxy floor coatings provide an attractive, high-performance surface. The high-gloss aesthetic forged by epoxy gives flooring a clean, sleek look. The design options are endless with epoxy. Decorative quartz, vinyl flake, self-leveling, and mortar epoxy present different styles and textures. Custom colors, patterns, and designs offer unlimited style selections.

The epoxy coating creates a safe, seamless covering. Epoxy flooring is beneficial for areas with slip and safety requirements, as well as areas susceptible to slippery (wet or dry) conditions. Slip-resistant epoxy floor coatings come in a multitude of texturized finishes, ranging from light to coarse. This slip-resistant epoxy coating will withstand the punishment of heavy machine traffic, chemical spills, and drastic changes in temperature. Current-day epoxy solutions produce little to no odor because of their low VOC content. This also results in a fast turn-around time during installation.

Why Hire Creative Maintenance Solutions?

Creative Maintenance Solutions is the leader in concrete coating solutions. Our Milwaukee based company has a nationwide reputation for providing high-level floor covering systems. For 30 years, Creative Maintenance Solutions has been the authority on epoxy flooring, polished concrete, and surface preparation.

Our continuing education programs allow us to provide state-of-the-art floor covering systems to companies throughout the country. We lay innovative flooring solutions to meet the specific needs of a variety of homes and businesses. Our client list boasts residential homeowners to Fortune 500 companies. The skilled staff at Creative Maintenance Solutions knows how to find real solutions that fit your needs, budgets, and deadlines.

For more information like our Choosing the Right Epoxy Flooring Company Checklist, visit our blog!

We lay the foundation for a safe and productive environment - every time!

Contact Creative Maintenance Solutions to learn more or to request an assessment of your concrete flooring project.