Great on Garage Floors, Kitchens, Bathrooms, Locker Rooms, Bars, Restaurants and more!

Flake floor coatings enhance the look of concrete flooring. Because of its unique aesthetic, flake floor coatings are growing in popularity among contractors and consumers alike. Whether you’re designing a commercial or industrial flooring plan to complement your brand or you’re a homeowner looking to add flair to your residential garage floor, vinyl flake floor coatings offer something for everyone.

Vinyl Flakes

At Creative Maintenance Solutions, we specialize in vinyl flake floor coatings, also known as vinyl color chips. While there are other color flake options on today’s market, like acrylic, the benefits of vinyl are vast. The unique qualities of this design element combined with a seamless, resilient epoxy coating create a durable, long-lasting floor.

Vinyl flakes lie flat, creating less space between and under the flakes. Vinyl flakes increase overall floor performance, protecting against gouges, scratches, and cracks. They even have sound-deadening qualities - perfect for noisy shops and warehouses.

Light Broadcast and Full Broadcast

There are two types of vinyl flake flooring applications: light broadcast and full broadcast. Although decorative flake floor coatings can be broadcast into an epoxy flooring system at varying levels in between, giving you the look you desire. The thin vinyl flakes are random in shape but have a standardized size range. There is no color bleed when they become wet. Applying flakes in varying thicknesses also changes the final product. Similar to other flooring options, texture can be added to intensify the complexion further.

Where to Use:

Garage Floors

Kitchens

Bathrooms

Locker Rooms

Bars

Restaurants

Car Dealerships

Showrooms

Mechanic Shops

Grocery and Retail Stores

Schools

Churches

Laundromats

Laboratories

Hospitals

The Application Process

The process of applying a vinyl flake epoxy flooring system involves multiple steps. The concrete substrate receives an application of a 100% solids broadcast with flakes. One or two topcoats of clear UV resistant 100% solids epoxy are then applied. These topcoats create an abrasion-resistant, easy-to-clean surface. Before installation, flooring experts consider humidity and temperature conditions, ensuring proper application.

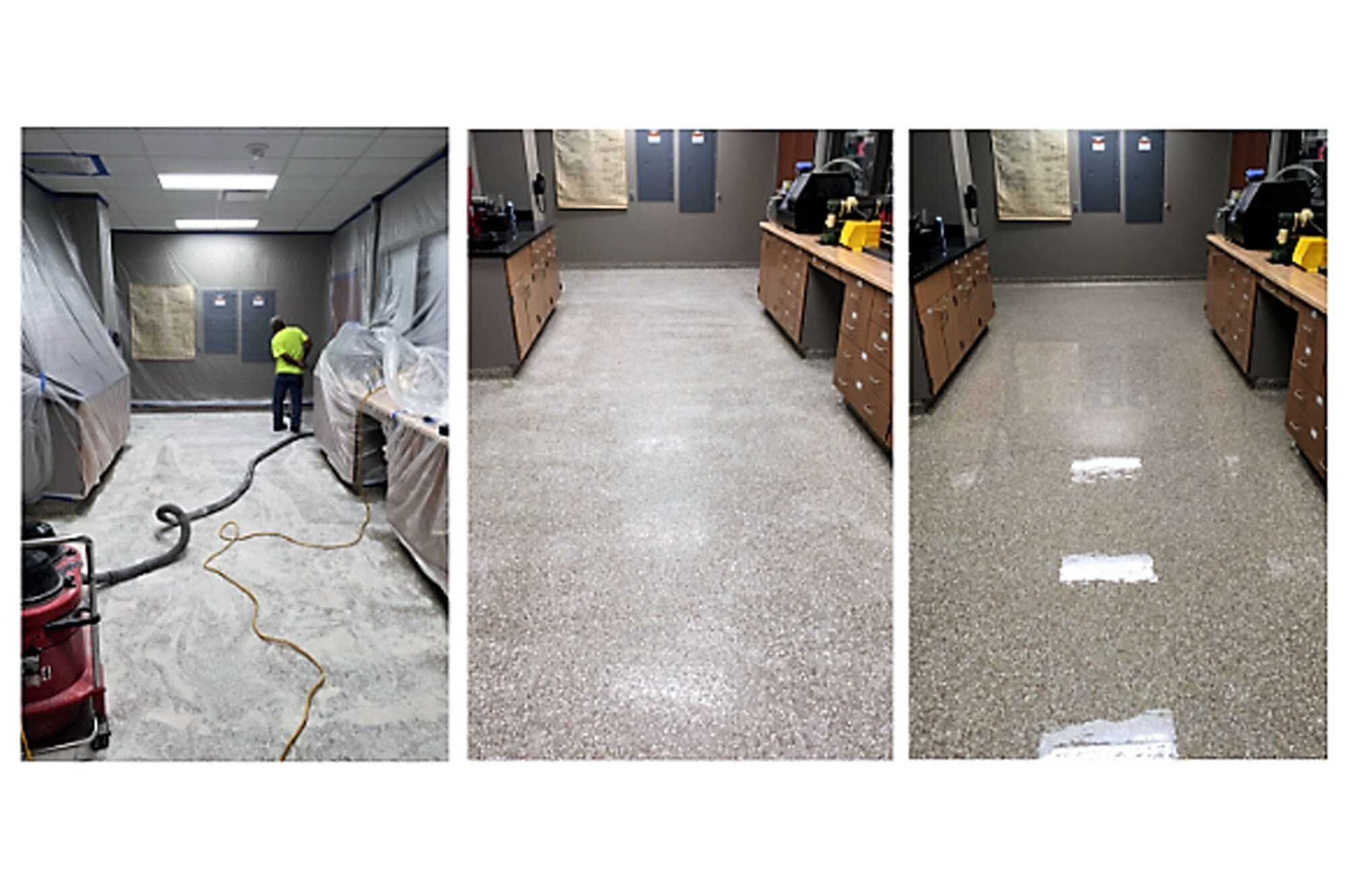

Take a look at the before and after of this residential garage. Creative Maintenance Solutions started this process by shot blasting the original floor. This cleans and opens concrete pores, ensuring the new floor will bond. Control joints were patched with epoxy mortar and ground smooth. The next steps included the application of a penetrating primer followed by a vinyl flake broadcast coat, covering the surface until no wet spots remain. Excess flakes are scraped and swept from the floor before the clear topcoats are applied.

An alluring floor finish sets your home or business apart. Vinyl flake floor coatings give your floor a sleek, professional appearance. If you’re interested in designing a vinyl flake floor, Creative Maintenance Solutions can help! Let us customize a state-of-the-art floor covering system for your home, commercial building, industrial facility, or institution.

Contact Creative Maintenance Solutions to start your project today!